Butt Weld Under Axial And Transverse Loading Calculator

A butt weld subjected to axial and transverse loading can experience both normal and shear stresses, which need to be considered for structural integrity. To calculate the stress distribution in such a weld, you would typically follow these steps:

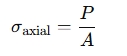

1. Axial Stress (σₓ)

Axial load (tension or compression) acts along the axis of the welded member. The stress due to axial loading is calculated as:

Where:

- is the axial load (force applied along the axis of the weld)

- is the cross-sectional area of the weld

If the cross-section of the weld is complex, you may need to use the effective throat area (Athroat) for calculation.

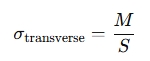

2. Transverse Stress (σᵧ)

Transverse loads (loads perpendicular to the axis of the weld) induce bending stresses in the welded joint. The bending stress is computed as:

Where:

- is the moment applied due to the transverse load

- is the section modulus of the weld

If the transverse load causes a moment about the center of the weld, would depend on the geometry of the weld and the distance from the center of rotation.

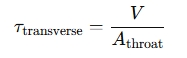

3. Shear Stress (τ)

Shear stress can be induced both from the axial and transverse loads, especially at the throat of the weld. It is calculated using the following equation for the axial shear:

And for transverse shear (if bending induces shear):

Where:

- is the transverse shear force

4. Combined Stress

When both axial and transverse loads are present, you need to consider the combined effect of normal and shear stresses. This can be done using the Von Mises criterion (for ductile materials) to find the effective stress:

Where is the combined shear stress resulting from both axial and transverse forces.

For a Simple Calculation:

-

Axial Load: Assume (in Newtons), the area of the weld section (in square millimeters), and calculate axial stress.

-

Transverse Load: For bending, calculate the moment based on the load and geometry, then use the section modulus to find transverse stress.