➔ Calculate Cutting Speed from Dia of job to be turned and Revolution of job

➔ Calculate Revolution(rev.) from Cutting Speed and Dia of job to be turned

➔ Calculate Time for Turning

➔ Calculate Time for Boring

➔ Calculate Time for Drilling

➔ Calculate Time for Facing

➔ Calculate Time for Knurling

➔ Calculate Time for Reaming

➔ Calculate Time for Tapping

Lathe Operations Calculator

A Lathe Operations Calculator typically helps determine key variables related to various lathe operations such as cutting speed, feed rate, and machining time. For lathe operations, there are a few standard formulas that can be applied, and I can guide you through them:

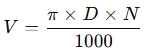

1. Cutting Speed (V)

The cutting speed is the speed at which the cutting tool moves relative to the workpiece. It is typically given in meters per minute (m/min) or feet per minute (ft/min). The formula is:

Where:

- = Cutting speed (m/min)

- = Diameter of the workpiece (mm)

- = Spindle speed (RPM)

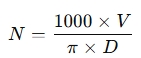

2. Spindle Speed (N)

The spindle speed is the number of revolutions per minute of the workpiece. It can be calculated using the following formula:

Where:

- = Spindle speed (RPM)

- = Cutting speed (m/min)

- = Diameter of the workpiece (mm)

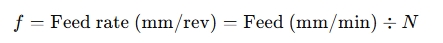

3. Feed Rate (f)

The feed rate is how fast the cutting tool advances along the workpiece per revolution of the spindle. It’s usually in mm/rev or inches/rev. The formula is:

Where:

- = Feed rate (mm/rev or in/rev)

- = Feed rate (mm/min or in/min)

- = Spindle speed (RPM)

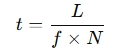

4. Cutting Time (t)

The time it takes to machine a workpiece depends on the length of the cut and the feed rate. The formula is:

Where:

- = Cutting time (minutes)

- = Length of cut (mm or inches)

- = Feed rate (mm/rev or in/rev)

- = Spindle speed (RPM)

Example:

Let’s say you are turning a workpiece with a diameter of 100 mm, a cutting speed of 120 m/min, and a feed rate of 0.2 mm/rev. You can calculate the spindle speed, feed rate, and machining time.