Calculate Pipe Friction Loss

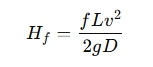

To calculate the friction loss in a pipe, the Darcy-Weisbach equation is commonly used. This equation helps determine the energy loss (head loss) due to friction as the fluid moves through the pipe. The equation is as follows:

Darcy-Weisbach Equation:

Where:

- Hf = Friction head loss (meters or feet)

- f = Friction factor (dimensionless)

- L = Length of the pipe (meters or feet)

- v = Velocity of the fluid (meters per second or feet per second)

- g = Acceleration due to gravity (9.81 m/s²)

- D = Diameter of the pipe (meters or feet)

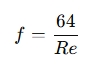

Friction Factor f:

The friction factor depends on the flow regime (laminar or turbulent) and the roughness of the pipe. For laminar flow, the friction factor is given by:

Where:

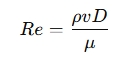

- Re = Reynolds number, which characterizes the flow regime and is calculated as:

Where:

- ρ = Density of the fluid (kg/m³)

- v = Velocity of the fluid (m/s)

- D = Diameter of the pipe (m)

- μ = Dynamic viscosity of the fluid (Pa·s)

For turbulent flow, the friction factor is often found using empirical formulas, such as the Colebrook-White equation or approximated using charts.

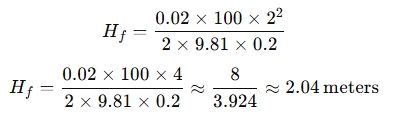

Example Calculation:

Let’s say we have the following information:

- Pipe length L = 100 meters

- Pipe diameter D = 0.2 meters

- Fluid velocity v = 2 m/s

- Friction factor f = 0.02 (assuming turbulent flow)

- Acceleration due to gravity g = 9.81 m/s²

Step 1: Plug the values into the Darcy-Weisbach equation:

So, the friction head loss Hf is approximately 2.04 meters.