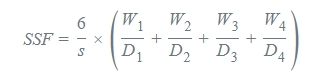

SSF = Standard Surface Factor

S = Specific Gravity of the Material

W = Fractional Weights of the Material

D = Average Diameters of the Material

Standard Surface Factor Calculator

A Standard Surface Factor (sometimes referred to as Surface Area Factor or Surface Roughness Factor) is typically used in engineering and fluid mechanics to quantify how the surface roughness of a material affects its interaction with fluids, such as in heat transfer, friction, or flow characteristics.

The exact meaning of Standard Surface Factor can vary based on the context (e.g., in heat exchangers, fluid flow, or material design). However, it usually relates to how a material’s surface roughness influences flow resistance, heat transfer efficiency, or other surface-related properties.

Common Areas of Use:

-

Fluid Flow and Friction:

- In fluid dynamics, rougher surfaces cause more turbulence and higher friction factors, which in turn increase resistance to flow. The surface factor can be used to calculate the Darcy friction factor or Colebrook equation for flow through rough pipes.

-

Heat Transfer:

- In heat exchangers, the surface roughness affects the heat transfer rate. A rougher surface can increase the turbulence of the fluid, improving heat transfer but increasing resistance.

-

Material Design:

- In structural applications, surface roughness factors may influence the strength, fatigue resistance, or wear properties of materials.

Surface Factor in Fluid Flow (e.g., Darcy Friction Factor):

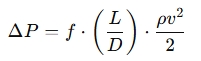

One way the surface roughness affects fluid flow is through the Darcy-Weisbach equation for frictional losses in pipes:

Where:

- ΔP = Pressure loss due to friction (Pa)

- f = Darcy friction factor, which depends on surface roughness

- L = Length of the pipe

- D = Diameter of the pipe

- ρ = Density of the fluid

- v = Flow velocity

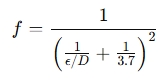

The Darcy friction factor (f) is influenced by the Reynolds number (Re) and the relative roughness of the pipe:

Where:

- ε = Surface roughness of the pipe (m)

- D = Diameter of the pipe (m)

This equation is often used for calculating the effect of pipe surface roughness on pressure drop and fluid flow.

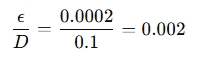

Example Calculation (Darcy Friction Factor):

Let’s say you have a pipe with the following parameters:

- Pipe diameter (D) = 0.1 m

- Surface roughness (ε) = 0.0002 m (smooth steel)

- Flow velocity (v) = 2 m/s

- Fluid density (ρ) = 1000 kg/m³

Calculate the relative roughness:

Now you can calculate the Darcy friction factor (f) using an equation or an online calculator.

Additional Considerations:

- For laminar flow, surface roughness has little effect on friction; only the Reynolds number matters.

- For turbulent flow, rougher surfaces lead to higher friction factors and pressure drops.

- Surface roughness also influences heat transfer rates, especially in heat exchangers, where turbulence can increase the heat exchange efficiency.